Description

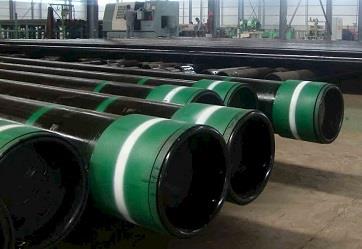

API 5CT Casing Pipe

Grade: H40, J55, K55, L80, L80-13Cr, L80-9Cr, N80-1, N80Q, P110

O.D: 4 1/2″-20″

Length: R1, R2, R3

Connection: STC, LTC, BTC, Premium Connection (VAM TOP, NEW VAM, PH-6)

Casing Pipe Data Table

| Labels a | OD mm |

Nominal Linear Mass b,c T&C kg/m |

WT t mm |

Type of end-finish d | ||||||||

| H40 | J55 K55 |

M65 | L80 R95 |

N80 Type 1, Q |

C90 T95 |

P110 | Q125 | |||||

| 1 | 2 | |||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 |

9.50 10.50 11.60 13.50 15.10 |

114.30 114.30 114.30 114.30 114.30 |

14.14 15.63 17.26 20.09 22.47 |

5.21 5.69 6.35 7.37 8.56 |

PS – – – – |

PS PSB PSLB – – |

PS PSB PLB PLB – |

– – PLB PLB – |

– – PLB PLB – |

– – PLB PLB – |

– – PLB PLB PLB |

– – – – PLB |

| 5 5 5 5 5 5 5 |

11.50 13.00 15.00 18.00 21.40 23.20 24.10 |

127.00 127.00 127.00 127.00 127.00 127.00 127.00 |

17.11 19.35 22.32 26.79 31.85 34.53 35.86 |

5.59 6.43 7.52 9.19 11.10 12.14 12.70 |

– – – – – – – |

PS PSLB PSLBE – – – – |

PS PSLB PLB PLB PLB – – |

– – PLB PLB PLB PLB PLB |

– – PLB PLB PLB PLB PLB |

– – PLB PLB PLB PLB PLB |

– – PLB PLB PLB PLB PLB |

– – – PLB PLB PLB PLB |

| 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 |

14.00 15.50 17.00 20.00 23.00 26.80 29.70 32.60 35.30 38.00 40.50 43.10 |

139.70 139.70 139.70 139.70 139.70 139.70 139.70 139.70 139.70 139.70 139.70 139.70 |

20.83 23.07 25.30 29.76 34.23 39.88 44.20 48.51 52.53 56.55 60.27 61.14 |

6.20 6.98 7.72 9.17 10.54 12.70 14.27 15.88 17.45 19.05 20.62 22.22 |

PS – – – – – – – – – – – |

PS PSLBE PSLBE – – – – – – – – – |

PS PSLB PLB PLB PLB – – – – – – – |

– – PLBE PLBE PLBE – – – – – – – |

– – PLBE PLBE PLBE – – – – – – – |

– – PLBE PLBE PLBE P P P P P P P |

– – PLBE PLBE PLBE – – – – – – – |

– – – – PLBE – – – – – – – |

| 6-5/8 6-5/8 6-5/8 6-5/8 |

20.00 24.00 28.00 32.00 |

168.28 168.28 168.28 168.28 |

29.76 35.72 41.67 47.62 |

7.32 8.94 10.59 12.06 |

PS – – – |

PSLB PSLBE – – |

PSLB PLB PLB – |

– PLBE PLBE PLBE |

– PLBE PLBE PLBE |

– PLBE PLBE PLBE |

– PLBE PLBE PLBE |

– – – PLBE |

| 7 7 7 7 7 7 7 |

17.00 20.00 23.00 26.00 29.00 32.00 35.00 |

177.80 177.80 177.80 177.80 177.80 177.80 177.80 |

25.30 29.76 34.23 38.69 43.16 47.62 52.09 |

5.87 6.91 8.05 9.19 10.36 11.51 12.65 |

PS PS – – – – – |

– PS PSLBE PSLBE – – – |

– PS PLB PLB PLB PLB – |

– – PLB PLB PLB PLB PLB |

– – PLB PLB PLB PLB PLB |

– – PLB PLB PLB PLB PLB |

– – – PLB PLB PLB PLBE |

– – – – – – PLB |

| 7 7 7 7 7 7 |

38.00 42.70 46.40 50.10 53.60 57.10 |

177.80 177.80 177.80 177.80 177.80 177.80 |

56.55 63.54 69.05 74.56 79.77 84.97 |

13.72 15.88 17.45 19.05 20.62 22.22 |

– – – – – – |

– – – – – – |

– – – – – – |

PLB – – – – – |

PLB – – – – – |

PLB P P P P P |

PLB – – – – – |

PLB – – – – – |

| 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 |

24.00 26.40 29.70 33.70 39.00 42.80 45.30 47.10 51.20 55.30 |

193.68 193.68 193.68 193.68 193.68 193.68 193.68 193.68 193.68 193.68 |

35.72 39.29 44.20 50.15 58.04 63.69 67.41 70.09 76.19 82.30 |

7.62 8.33 9.52 10.92 12.70 14.27 15.11 15.88 17.45 19.05 |

PS – – – – – – – – – |

– PSLB – – – – – – – – |

– PSLB PLB PLB – – – – – – |

– PLB PLB PLB PLB PLB PLB PLB – – |

– PLB PLB PLB PLB PLB PLB PLB – – |

– PLB PLB PLB PLB PLB PLB PLB P P |

– – PLB PLB PLB PLB PLB PLB – – |

– – – – PLB PLB PLB PLB – – |

| 7-3/4 | 46.10 | 196.85 | 68.60 | 15.11 | – | – | – | P | P | P | P | P |

| 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 |

24.00 28.00 32.00 36.00 40.00 44.00 49.00 |

219.08 219.08 219.08 219.08 219.08 219.08 219.08 |

35.72 41.67 47.62 53.57 59.53 65.48 72.92 |

6.71 7.72 8.94 10.16 11.43 12.70 14.15 |

– |

PS PS – PSLB PSLB PLB – |

PS PS PSLB PSLB PLB – – |

– – – PLB PLB PLB PLB |

– – – PLB PLB PLB PLBE |

– – – PLBE PLBE PLBE PLBE |

– – – PLB PLB PLB |

– – – – – PLB |

| 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 |

32.30 36.00 40.00 43.50 47.00 53.50 58.40 59.40 64.90 70.30 75.60 |

244.48 244.48 244.48 244.48 244.48 244.48 244.48 244.48 244.48 244.48 244.48 |

48.07 53.57 59.53 64.73 69.94 79.62 86.91 88.40 96.58 104.62 112.50 |

7.92 8.94 10.03 11.05 11.99 13.84 15.11 15.47 17.07 18.64 20.24 |

PS PS – – – – – – – – – |

– PSLB PSLB – – – – – |

– PSLB PSLB PLB PLB – – – – – |

– – PLB PLB PLB PLB PLB – – – – |

– – PLB PLB PLB PLB PLB – – – |

– – PLB PLB PLB PLB PLB P P P P |

– – – PLB PLB PLB PLB – – – – |

– – – – PLB PLB PLB – – – – |

| 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 |

32.75 40.50 45.50 51.00 55.50 60.70 65.70 73.20 79.20 85.30 |

273.05 273.05 273.05 273.05 273.05 273.05 273.05 273.05 273.05 273.05 |

48.74 60.27 67.71 75.90 82.59 90.33 97.77 108.93 117.86 126.94 |

7.09 8.89 10.16 11.43 12.57 13.84 15.11 17.07 18.64 20.24 |

PS PS – – – – – – – – |

– PSB PSB PSB – – – – – – |

– PSB PSB PSB PSB – – – – – |

– – – PSB PSB – – – – – |

– – – PSB PSB – – – – – |

– – – PSB PSB PSB PSB P P P |

– – – PSB PSB PSB PSB – – – |

– – – – – PSB PSB – – – |

| 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 |

42.00 47.00 54.00 60.00 65.00 71.00 |

298.45 298.45 298.45 298.45 298.45 298.45 |

62.50 69.94 80.36 89.29 96.73 105.66 |

8.46 9.53 11.05 12.42 13.56 14.78 |

PS – – – – – |

– PSB PSB PSB – – |

– PSB PSB PSB – – |

– – – PSB P P |

– – – PSB P P |

– – – PSB P P |

– – – PSB P P |

– – – PSB P P |

| 13-3/8 13-3/8 13-3/8 13-3/8 13-3/8 |

48.00 54.50 61.00 68.00 72.00 |

339.72 339.72 339.72 339.72 339.72 |

71.43 81.10 90.78 101.19 107.15 |

8.38 9.65 10.92 12.19 13.06 |

PS – – – – |

– PSB PSB PSB – |

– PSB PSB PSB – |

– – – PSB PSB |

– – – PSB PSB |

– – – PSB PSB |

– – – PSB PSB |

– – – – PSB |

| 16 16 16 16 |

65.00 75.00 84.00 109.00 |

406.40 406.40 406.40 406.40 |

96.73 111.61 125.01 162.21 |

9.53 11.13 12.57 16.66 |

PS – – – |

– PSB PSB P |

– PSB PSB – |

– – – P |

– – – P |

– – – – |

– – – P |

– – – P |

| 18-5/8 | 87.50 | 473.08 | 130.21 | 11.05 | PS | PSB | PSB | – | – | – | – | – |

| 20 20 20 |

94.00 106.50 133.00 |

508.00 508.00 508.00 |

139.89 158.49 197.93 |

11.13 12.70 16.13 |

PSL – – |

PSLB PSLB PSLB |

PSLB PSLB – |

– – – |

– – – |

– – – |

– – – |

– – – |

| P=Plain end; S=short round thread; L=Long round thread; B–Buttress thread; | ||||||||||||

| a: Labels are for information and assistance in ordering. b: Nominal linear masses (col. 4) are shown for information only. c: The densities of martensitic chromium steels (L80 Types 9Cr and 13Cr) are different from carbon steels. The masses shown are therefore not accurate for martensitic chromium steels. A mass correction factor of 0.989 may be used. d: Buttress casing i s available with regualr, special clearance coupings or special clearance couplings with special bevel. | ||||||||||||

API 5CT MATERIALS CHEMICAL COMPOSITION

| Group | Grade | Type | C | Mn | Mo | Cr |

Ni max |

Cu max |

P max |

S max |

Si max |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min | max | min | max | min | max | min | max | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | H40 | – | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.03 | – |

| J55 | – | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.03 | – | |

| K55 | – | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.03 | – | |

| N80 | 1 | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.03 | – | |

| N80 | Q | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.03 | – | |

| R95 | – | – | 0.45 c | – | 1.9 | – | – | – | – | – | – | 0.03 | 0.03 | 0.45 | |

| 2 | M65 | – | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.03 | – |

| L80 | 1 | – | 0.43 a | – | 1.9 | – | – | – | – | 0.25 | 0.35 | 0.03 | 0.03 | 0.45 | |

| L80 | 9Cr | – | 0.15 | 0.3 | 0.6 | 0.9 | 1.1 | 8 | 10 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| L80 | 13Cr | 0.15 | 0.22 | 0.25 | 1 | – | – | 12 | 14 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| C90 | 1 | – | 0.35 | – | 1.2 | 0.25 b | 0.85 | – | 1.5 | 0.99 | – | 0.02 | 0.01 | – | |

| T95 | 1 | – | 0.35 | – | 1.2 | 0.25 d | 0.85 | 0.4 | 1.5 | 0.99 | – | 0.02 | 0.01 | – | |

| C110 | – | – | 0.35 | – | 1.2 | 0.25 | 1 | 0.4 | 1.5 | 0.99 | – | 0.02 | 0.005 | – | |

| 3 | P110 | e | – | – | – | – | – | – | – | – | – | – | 0.030 e | 0.030 e | – |

| 4 | Q125 | 1 | – | 0.35 | 1.35 | – | 0.85 | – | 1.5 | 0.99 | – | 0.02 | 0.01 | – | |

| a The carbon content for L80 may be increased up to 0.50 % maximum if the product is oil-quenched. b The molybdenum content for Grade C90 Type 1 has no minimum tolerance if the wall thickness is less than 17.78 mm. c The carbon content for R95 may be increased up to 0.55 % maximum if the product is oil-quenched. d The molybdenum content for T95 Type 1 may be decreased to 0.15 % minimum if the wall thickness is less than 17.78 mm. e For EW Grade P110, the phosphorus content shall be 0.020 % maximum and the sulfur content 0.010 % maximum. NL = no limit. Elements shown shall be reported in product analysis. |

|||||||||||||||

CASING PIPE MATERIALS – MECHANICAL PROPERTIES

| Group |

Grade |

Type |

Total elongation under load % |

Yield strength MPa |

Tensile strength min. MPa |

Hardness a max. |

Specified wall thickness mm |

Allowable hardness variation b HRC |

||

|---|---|---|---|---|---|---|---|---|---|---|

| min | max | HRC | HBW | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 | H40 | – | 0.5 | 276 | 552 | 414 | – | – | – | – |

| J55 | – | 0.5 | 379 | 552 | 517 | – | – | – | – | |

| K55 | – | 0.5 | 379 | 552 | 655 | – | – | – | – | |

| N80 | 1 | 0.5 | 552 | 758 | 689 | – | – | – | – | |

| N80 | Q | 0.5 | 552 | 758 | 689 | – | – | – | – | |

| R95 | – | 0.5 | 655 | 758 | 724 | – | – | – | – | |

| 2 | M65 | – | 0.5 | 448 | 586 | 586 | 22 | 235 | – | – |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 | – | – | |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | – | – | |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | – | – | |

| C90 | 1 | 0.5 | 621 | 724 | 689 | 25.4 | 255 |

≤ 12.70 12.71 to 19.04 19.05 to 25.39 ≥ 25.40 |

3.0 4.0 5.0 6.0 | |

| T95 | 1 | 0.5 | 655 | 758 | 724 | 25.4 | 255 |

≤ 12.70 12.71 to 19.04 19.05 to 25.39 ≥ 25.40 |

3.0 4.0 5.0 6.0 | |

| C110 | – | 0.7 | 758 | 828 | 793 | 30 | 286 |

≤ 12.70 12.71 to 19.0 19.05 to 25.39 ≥ 25.40 |

3.0 4.0 5.0 6.0 | |

| 3 | P110 | – | 0.6 | 758 | 965 | 862 | – | – | – | – |

| 4 | Q125 | 1 | 0.65 | 862 | 1034 | 931 | b | – |

≤ 12.70 12.71 to 19.04 ≥ 19.05 |

3.0 4.0 5.0 |

| a In case of dispute, laboratory Rockwell C hardness testing shall be used as the referee method. b No hardness limits are specified, but the maximum variation is restricted as a manufacturing control in accordance with 7.8 and 7.9 of API Spec. 5CT. |

||||||||||

Hot Tags: api 5ct H40, J55, K55, L80, L80-13Cr, L80-9Cr, N80-1, N80Q, P110 casing pipe, China, manufacturers, suppliers, factory, company, exporter, seller, brands, import, buy, best, high-quality

HSH stocks a broad range of metal materials, including aluminum, steel, stainless steel, copper and brass, and specialty metals. Also, we also sell cast fittings, cast Iron, forged fittings, cutting tools, flanges, ect. If you have any needs about our products, you can contact us.

sales@metal-pipe.com

,

HSH stocks a broad range of metal materials, including aluminum, steel, stainless steel, copper and brass, and specialty metals. Also, we also sell cast fittings, cast Iron, forged fittings, cutting tools, flanges, ect. If you have any needs about our products, you can contact us.

sales@metal-pipe.com