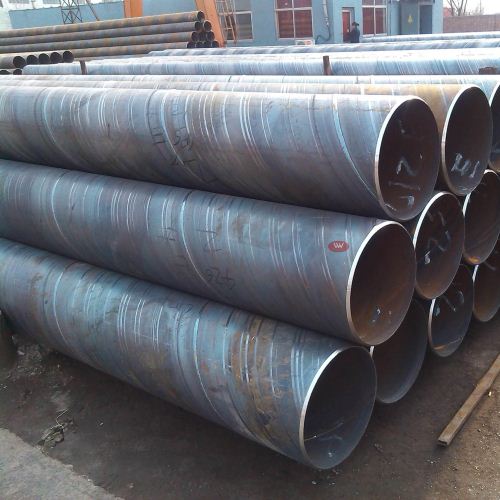

The Material, Advantages And Disadvantages Of Spiral Welded Pipe

1. Definition of spiral welded pipe

Spiral welded pipe: It is made by rolling low-carbon carbon structural steel or low-alloy structural steel strip according to a certain spiral angle (called forming angle) into a tube blank, and then welding the tube seam together. It can be made with a narrower Strip steel produces large diameter steel pipes. The specifications are expressed in terms of outer diameter and wall thickness. The welded pipe shall ensure that the water pressure test, the tensile strength of the weld seam and the cold bending performance meet the requirements.

2. Material of spiral welded pipe

Q235A, Q235B, 0Cr13, 1Cr17, 00Cr19Ni11, 1Cr18Ni9, 0Cr18Ni11Nb, 16Mn, 20#, Q345, L245, L290, 40#, 60#, X42, X46, X70, X80.

3. The use of spiral welded pipe

Spiral welded pipes are mainly used in water supply engineering, petrochemical industry, chemical industry, electric power industry, agricultural irrigation, and urban construction in China. Used for liquid transportation: water supply and drainage. Used for gas transportation: coal gas, steam, liquefied petroleum gas. For structural purposes: as piling pipes and bridges; pipes for docks, roads, and building structures.

4. Calculation formula of theoretical weight per meter of spiral welded pipe

Spiral welded pipe is divided into delivery according to actual weight or delivery according to theoretical weight

Actual weight-at the time of delivery, the weight of the product is delivered according to the weighed (weighed) weight;

Theoretical weight-at the time of delivery, the weight of the product is the weight calculated according to the nominal size of the steel. The calculation formula is as follows (if delivery is required according to the theoretical weight, it must be indicated in the contract):

The calculation formula for the theoretical weight of spiral welded pipe per meter: W=0.0246615 (D-S) S+0.5

In the formula: W–theoretical weight of spiral welded pipe per meter, kg/m;

D–Nominal outer diameter of spiral welded pipe, mm;

S–Nominal wall thickness of spiral welded pipe, mm.

5. Advantages and disadvantages of spiral welded pipe

Advantages of spiral welded pipe:

(1) Steel pipes of different diameters can be produced using strip steel of the same width, especially narrow strip steel can be used to produce large diameter steel pipes.

(2) Under the same pressure conditions, the stress of the spiral welded seam is smaller than that of the straight seam, which is 75% to 90% of that of the straight seam welded pipe, so it can withstand greater pressure. Compared with the straight seam welded pipe of the same outer diameter, the wall thickness can be reduced by 10% to 25% under the same pressure.

(3) The size is accurate, the general diameter tolerance does not exceed 0.12%, the deflection is less than 1/2000, and the ovality is less than 1%. Generally, the sizing and straightening process can be omitted.

(4) It can be produced continuously, theoretically it can produce infinitely long steel pipes, the loss of cutting head and tail is small, and the metal utilization rate can be increased by 6% to 8%.

(5) Compared with the straight seam welded pipe, its operation is flexible, and it is convenient to change and adjust the variety.

(6) The equipment is light in weight and low initial investment. It can be made into a trailer-type mobile unit to directly produce welded pipes at the construction site where the pipeline is laid.

(7) It is easy to realize mechanization and automation.

The disadvantages of spiral welded pipe are: due to the use of rolled strip steel as raw material, there is a certain crescent curve, and the welding point is in the edge area of the elastic strip, so it is not easy to align the welding torch, which affects the welding quality. To this end, it is necessary to set up complex welding seam tracking and quality inspection equipment.

HSH stocks a broad range of metal materials, including aluminum, steel, stainless steel, copper and brass, and specialty metals. Also, we also sell cast fittings, cast Iron, forged fittings, cutting tools, flanges, ect. If you have any needs or questions, you can contact us.